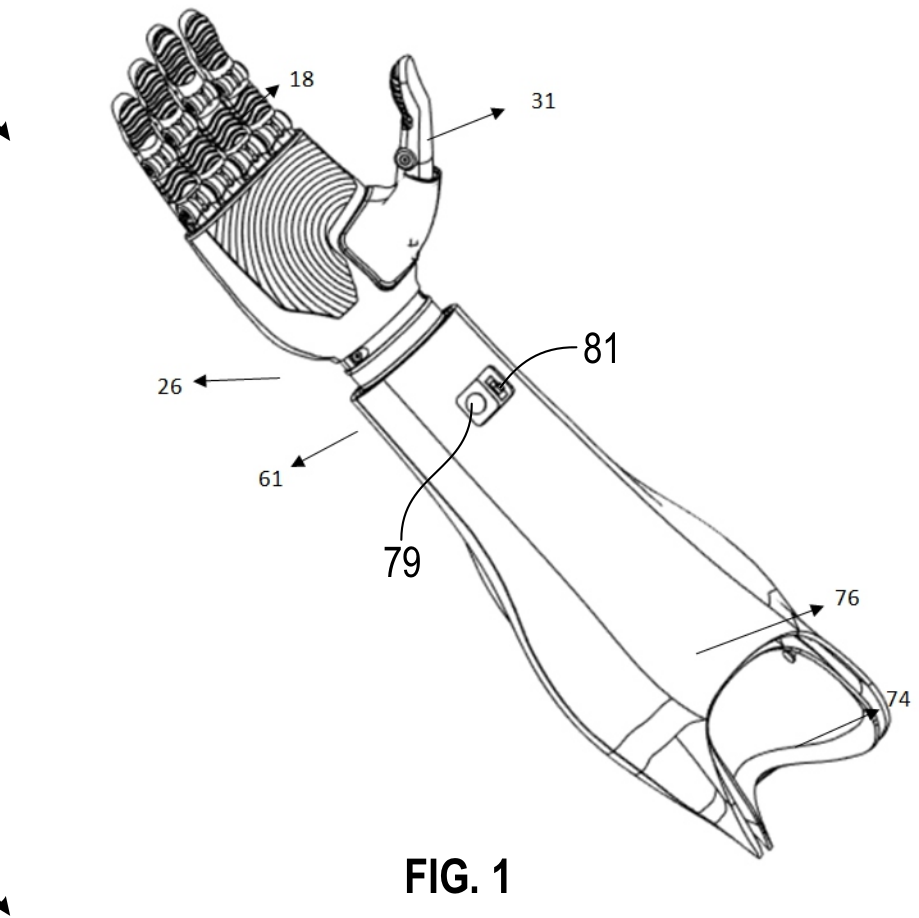

KalArm

India's First Bionic Hand

KalArm is an underactuated robotic hand prosthesis solution developed by a 10 member team including Ananth Rachakonda at Makershive Innovations Pvt. Ltd. It has been engineered to feature the range of dexterity and motion of some of the most advanced commercial prosthesis available like the Ottobock be-bionic and the Taska hand at a \(10^{th}\) of their cost. Optimising the cost while maintaining the feature set required for some clever engineering, design and manufacturing choices. The software stack of the product is specially engineered to alleviate the limitations of certain engineering choices that make the hand more affordable. It connects with a customisable cross-platform application to offer the usage statistics and also performs software updates on the go. It features custom designed EMG sensors and associated pattern recognition firmware, and linear actuators attached to a compliant hybrid tendon drive for operational safety. The hand features 16 grips in 4 modes allowing the user to perform a wide range of tasks a few of which are force-based. It uses 3D printing technology to offer custom fit for the user while the exterior is completely manufactured using additive manufacturing. The hand is controlled using surface electromyography in tandem with a multifunctional switch to change modes of operation.

Mile Markers:

-

Designed and developed high-speed signal processing and pattern recognition algorithms for non-deterministic signals with optimized time and space constraints in a single thread architecture.

-

Designed FSM Decision Tree based control algorithms for closed-loop control of the bionic arm.

-

Initiated, extensively developed, and delivered industry-standard low-level drivers for all the peripherals of KalArm.

-

Designed and developed the entire wireless communication stack of KalArm.

-

Ideated, developed, and tested KalArm’s data visualization pipeline and its accompanying cross-platform application.

-

Identified, developed, and optimized multiple operation strategies that drastically improve the trainability and usability of the product.

-

Conceived the multi-controller architecture, designed and developed distributed control algorithms for various nodes of KalArm to enhance the performance of KalArm in the latest iteration.

-

Developed a novel mechanism to transduce the position of individual fingers in the robotic prosthesis.

-

Designed and developed sensor fusion algorithms for precise position control of high-speed brushed and brushless motors and the linear actuator system.

-

Designed and developed algorithms for control of underactuated tendon and link-based finger mechanisms.

-

Modeled and developed the handshake grip - which firmly grasps a hand during the gesture while taking into account the shape and firmness of the grasp - without the aid of active force feedback.

-

Modeled and developed the adaptive grasp grip -which can be used to hold delicate objects of various shapes and rigidities while accounting for allowable squish - without the aid of active force feedback.

-

Achieved over a tenth of a degree of precision in position control of the fingers of the robotic prosthesis that has entirely been produced using additive manufacturing while compensating dynamically for all non-linearities.

-

Ideated, designed, and developed software testbeds to evaluate the performance of various discrete units of the bionic arm and the robotic prosthesis as a whole.

-

Developed software for the entire automated assembly line of the product to match ISO 13485:2016

The patent is published, and granted. The patent number is : 398775

and can be found here

References

2022

-

A Fully Functional Bionic ArmJun 2022Granted by IP India, Office of the CGPDTM, Dept. of Ind. Policy and Promo., Ministry of Commerce and Industry, Govt. of India

A Fully Functional Bionic ArmJun 2022Granted by IP India, Office of the CGPDTM, Dept. of Ind. Policy and Promo., Ministry of Commerce and Industry, Govt. of India